3 min read

Pulp and Paper Industry Roundup: Developments in 1Q2024

The beginning of 2024 witnessed a series of unexpected developments within the pulp and paper industry, creating rippling impacts across the sector....

3 min read

The beginning of 2024 witnessed a series of unexpected developments within the pulp and paper industry, creating rippling impacts across the sector....

2 min read

Renewable energy is brimming with promise, shining a light on sustainability and eco-friendly practices. The RFS-2 legislation emphasizes the...

2 min read

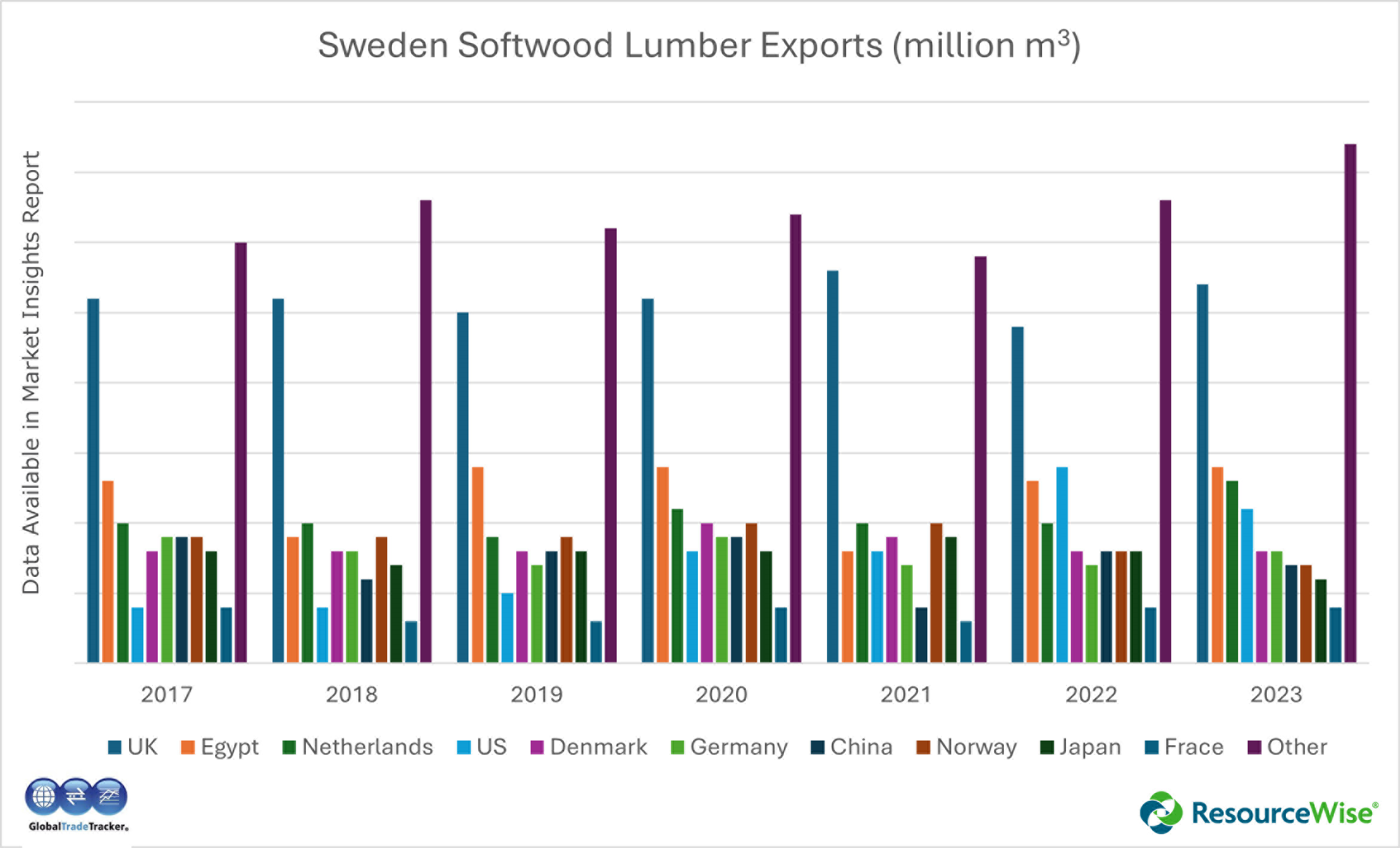

Sweden's softwood lumber export sector is a bright spot despite an economy steeped in recession. Export sawmills are optimistic that demand from the...

2 min read

For the first time in over 80 years, the highly respected Clallam Tree Farm, a highly esteemed timberland portfolio on the Olympic Peninsula, has...

3 min read

With the ongoing momentum in corporate sustainability initiatives, the collaboration between pulp and paper companies and major corporations to...

1 min read

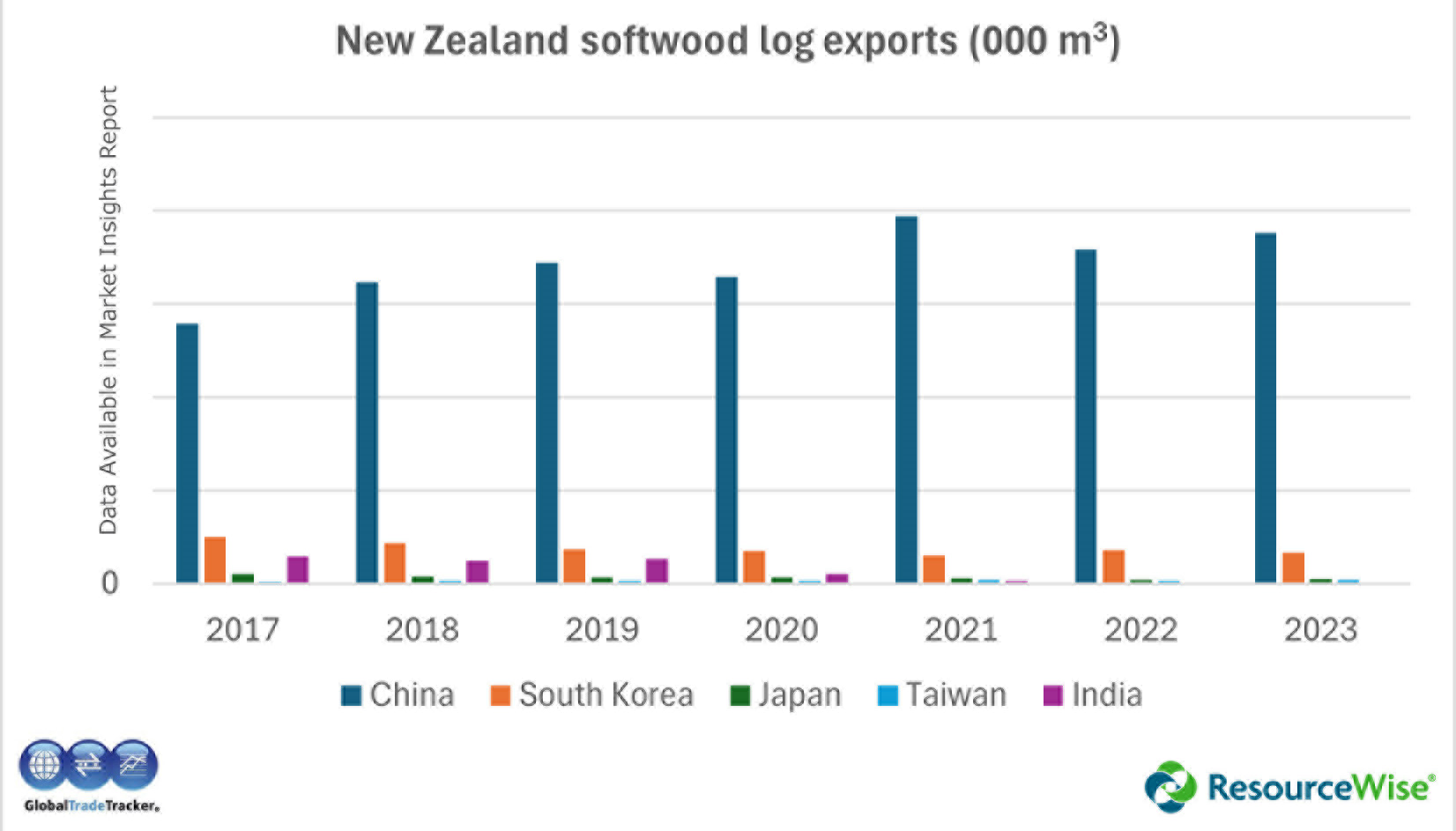

Reflecting on New Zealand's softwood log exports to China in 2023, ResourceWise data indicates a 5% increase compared to 2022. However, a closer look...

3 min read

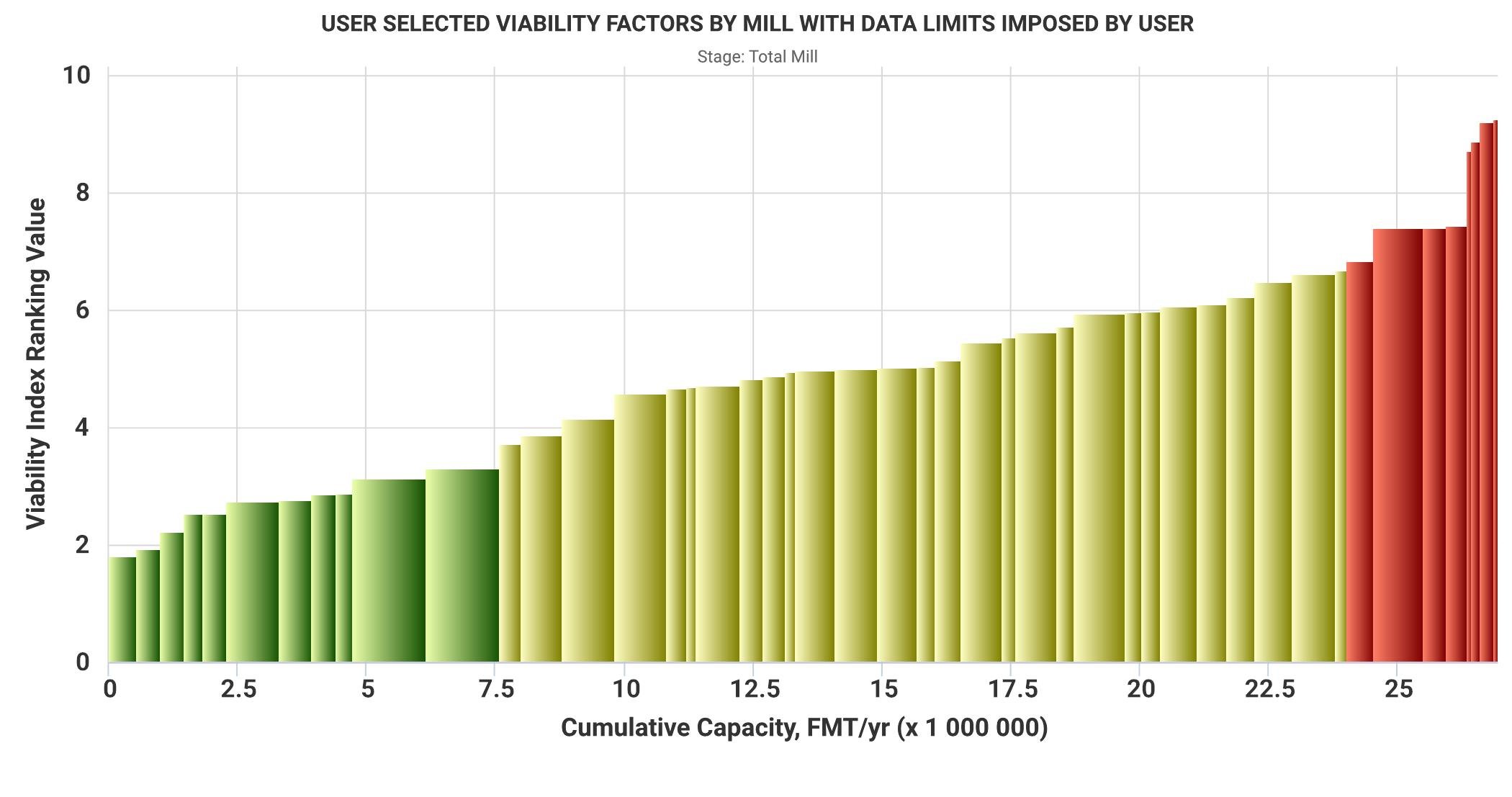

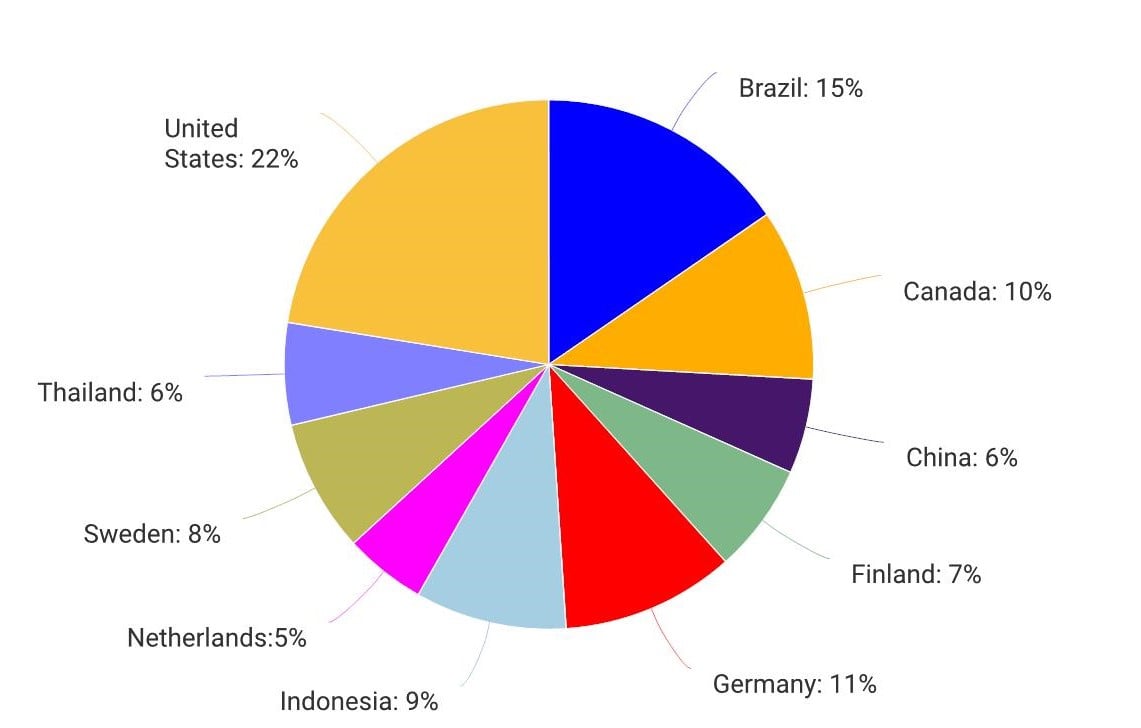

When looking forward at the forces that are likely to drive the direction of the pulp and paper industry over the next 15 years, decarbonization and...

2 min read

The consumer goods space has not only expanded significantly in recent years but has also shifted towards more eco-friendly practices. With...

2 min read

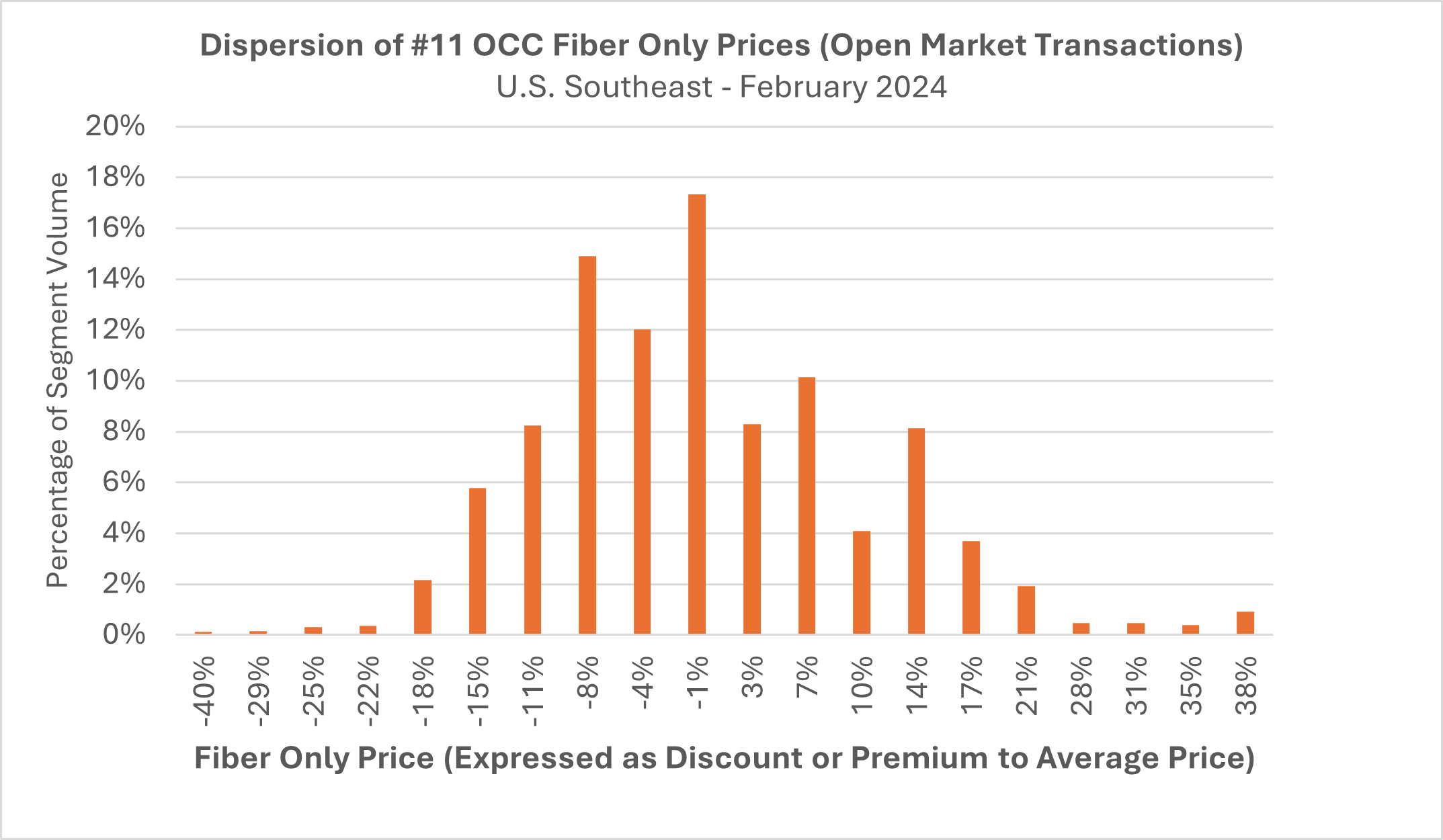

An executive once told me, "Variance is not just a challenge, but an opportunity for management." While variance might create frustration and fear of...

2 min read

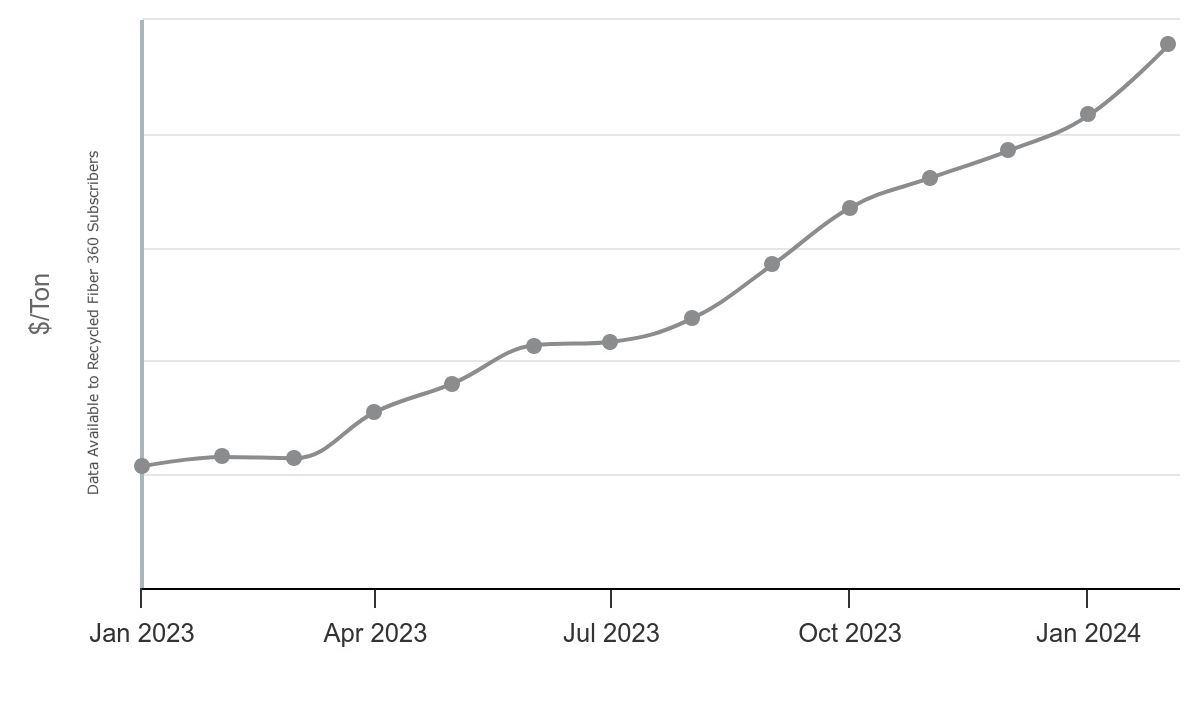

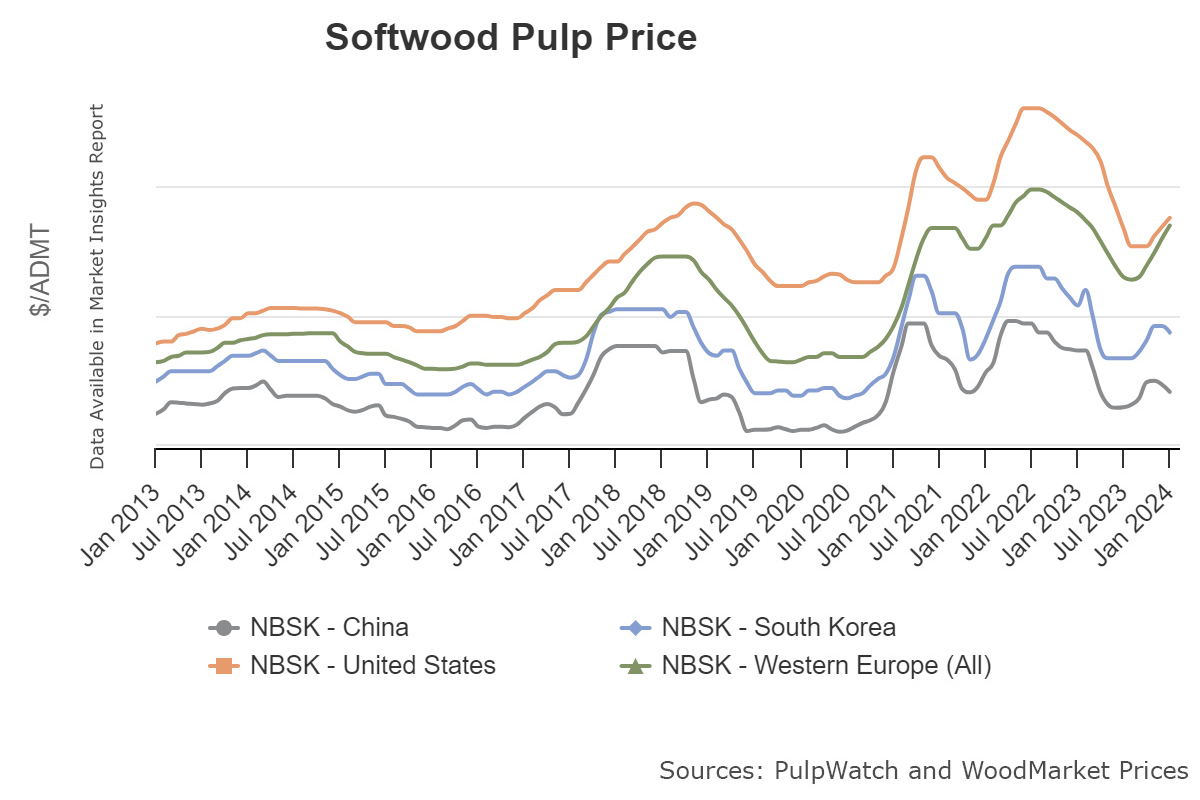

The global pulp market has seen its fair share of ups and downs, making it a highly volatile and unpredictable industry. The trend of global pulp...

2 min read

The forestry industry of Mississippi is bracing itself for a game-changing shift, following President Biden's recent signing of the FY2024...

3 min read

On March 11, labor unions in Finland initiated a two-week strike that is poised to have a significant impact on the nation's export and import...