Making Obvious What Adds Value by Reducing Everything Else

Lean manufacturing[1], a customer-focused management philosophy for waste elimination and quality improvement, focuses—as is often said—on making obvious what adds value by reducing everything else. One of the foundations of lean manufacturing is the Japanese concept of Kaizen, a striving for continuous, daily improvement. Continuous improvement is a comprehensive concept that requires meticulous attention to detail and nimble operating procedures to sustain it. For the forest products industry—an industry that is diverse and susceptible to the effects of myriad market variables—lean manufacturing can bring tangible value to the supply chain and increase profits.

Opportunities for Improvement

As we noted in a post earlier in the month, the wood fiber supply chain involves so much more than moving raw materials from point A to point B; it is a complex system that is constantly affected by a number of variables between point A and point B. While there is no silver bullet for eliminating unforeseen challenges along the way—from waste to inefficiencies to unnecessary costs—there are steps that organizations can take to mitigate risks and optimize their supply chains. How does one formulate a basis for identifying cost-saving opportunities, and how does such a process begin? With cold, hard data.

Quality data is what differentiates a Kaizen-derived strategy from a reactionary lurch towards a lofty ideal. For instance, the DMAIC improvement cycle associated with the renowned Six Sigma methodology begins with a concrete process:

-

Define: Identify the problem and define the scope of improvements

-

Measure: Collect business data

-

Analyze: Conduct root cause analysis

-

Improve: Develop potential solutions and evaluation criteria

-

Control: Monitor progress and make adjustments

Such a process must begin by utilizing the correct data. Without access to the most reliable set of data during steps one and two, the remaining steps in the process will be inadequate and the solutions will be misguided. Some improvements may be realized initially, but subsequent improvement cycles will likely result in diminishing returns simply because the process didn’t begin with the right set of data.

Supply Chain Optimization

Tangible and lasting business improvements begin with the appropriate tools and Forest2Market has the most robust set of data available to the market. With over 220 million rows of validated, expertized and transaction-based data, this resource is the foundation for forest products organizations to successfully implement Kaizen and optimize their wood fiber supply chains. At a high level, the process seeks to convert data into intelligence, intelligence into action, and action into advantage.

Taking the analysis a step further, the methodology for optimizing the wood fiber supply chain is similar to the DMAIC approach in that it begins by analyzing and defining the scope of the business’s goals. Once this determination has been made, the process follows a comparable path towards improvement based on the reliability of transaction-based data:

-

Identify market position and set goals

-

Uncover inefficiencies, issues and their root causes

-

Develop and implement strategic solutions

-

Measure the results

-

Repeat the process

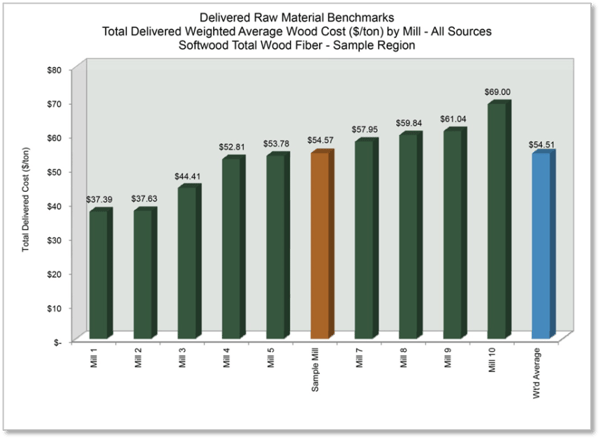

It should be noted that, just as Kaizen represents the continuous practice of improvement, the supply chain optimization process is designed to be both flexible and cyclical as well. Its nimbleness allows for the analysis of any number of custom criteria including geography, species type, mill type and mill consumption just to name a few. For example, the graph below illustrates the total delivered wood costs of 10 mills, highlighting the market position of a sample mill (orange). This kind of accurate, reliable data—down to the penny, in fact—is the basis for identifying a true market position in step one, so that the sample mill in this case can move through the improvement process with confidence.

-

Step two will take the analysis even further by breaking out individual components such as freight costs, fiber costs and total overhead from each of the 10 mills. From this vantage point, the process will begin to uncover true problem areas and inefficiencies within the supply chain.

-

Step three will provide the framework for implementing a set of solutions for the problem areas—strategies for sifting out systemic noise--including developing the evaluation criteria for measuring the success.

-

Step four will provide detailed measurements of the refinements and solutions. From this final phase of the process, it is simply a matter of interpreting the results to gauge the success of this particular supply chain optimization cycle.

Organizations that leverage the principles of lean manufacturing are inherently advantaged within the market. These organizations remain agile and are able to quickly adapt to changing market dynamics because they are constantly setting goals, analyzing performance and measuring results. As a set of tools that can help organizations make obvious what adds value and reduce procurement system noise, Forest2Market’s Supply Chain Optimization Program is a streamlined way for companies using wood raw materials to implement a similar process of improvement, one that is customizable to each business and uniquely designed for the forest products industry. With superior data and a precise set of tools, optimizing the supply chain becomes a manageable and measurable task.

[1] As Japan began to rebuild after the war, Toyota Manufacturing developed an integrated, organizational development structure called the Toyota Production System (TPS) that comprises its management philosophy and business practices. The TPS is responsible for organizing manufacturing and logistics operations for the automobile manufacturer and, at a very high level, the TPS seeks to phase out and redesign areas of overburden and inconsistency, and to eliminate waste. The system has been integral to the success of the company over the last 60+ years, and has served as a launch pad for a number of process improvement schemes that are commonplace in today’s business environment, including lean manufacturing.