5 min read

Wood Construction: Good for Communities, Good for the Environment

John Greene

:

February 23, 2017

Per a recent article in the Winter Park/Maitland Observer, the City Council of Maitland, Fla. (which is just north of Orlando) is actively seeking to ban wood-frame construction for new buildings in the town of roughly 16,500 residents. After getting on board with the city’s Planning & Zoning Commission proposal to ditch wood construction in all new structures (aside from single-family homes), the Council’s lobbyist has gone to work to gain the support of the state legislature in hopes of changing Florida building codes to allow more local control in the choice of building materials.

Planning & Zoning Commission member Barry Kalmanson recently told the Council that “It’s all about quality. If you want a quality community you have to build it right… Not Styrofoam, not wood-frame construction. It doesn’t work.” Kalmanson also said that building multi-family structures out of concrete or steel would make them more “sustainable” in the long run, as he is concerned about how wood-framed units will age. “They’ll look beautiful the day they’re built. But 10 or 20 or 30 years later, that’s the problem,” he added.

But history demonstrates otherwise: Wood-based Westminster Hall in London has stood since the time of Henry VIII over 700 years ago, and Greensted Church in southern England has stood for nearly 1,000 years—the oldest wooden church in the world. Modern technology—which is helping to develop new wood-based construction materials such as Cross Laminated Timber (CLT)—also demonstrates otherwise. Wood-based building materials are cost-effective and widely available, durable, versatile and much more environmentally friendly than many other building materials.

Interior of the oldest wooden church in the world. Image Courtesy of Greensted Church

Wood Costs Less

Wood can be locally sourced and is typically readily available and less expensive than many alternative building materials. Wood building systems typically cost less to install than other structural materials and, due to wood’s popularity, wood contractors are widely available. Wood’s relative light weight can also reduce the need for foundation capacity, resulting in substantial cost savings. (Visit woodworks.org for a list of detailed commercial-scale case studies demonstrating wood’s cost effectiveness vs. other materials.)

Wood is Durable

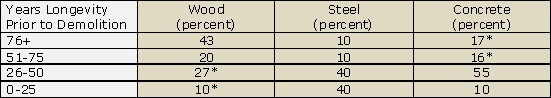

In Suz-Anne Kinney’s post on this very topic in 2009, she notes that “One of the misconceptions about using wood in non-residential construction concerns its durability. With proper design and construction techniques and regular maintenance, however, wood structures are extremely durable. A survey of commercial structures demolished between 2000 and 2003 in Minneapolis/St. Paul, Minnesota demonstrates this. Though the sampling of the study is small, approximately 100 structures built of concrete, steel and wood, wood had the longest lifespan of the three building materials.”

The following table is compiled from the study, which was undertaken by Jennifer O’Connor, a research scientist with Canadian firm, Forintek.

Source: http://www.woodworks.org/files/PDF/keyIssues/SurveyonActualServiceLives.pdf

*Percentages are approximate, as the graphs published in the study do not include exact data points in some cases.

In addition, O'Connor concluded that "the service life of most buildings are probably far shorter than their theoretical maximum lives. While wood is believed to have a short life expectancy due to risk of fire or biodegradation, the wood buildings in our study had the longest life spans."

And as Hannah Jefferies noted last September, Cross Laminated Timber and other wood-engineered products are gaining popularity among builders for a number of reasons. “The 2015 International Building Code and 2015 International Residential Code now recognize CLT manufactured in accordance with the Standard for Performance Rated Cross-Laminated Timber (ANSI/APA PRG 320), which was approved by the American National Standards Institute on October 30, 2012. The 2015 IBC allows CLT to be used in residential structures up to five stories and certain ‘heavy-timber’ commercial structures up to six stories.”

Four-story Candlewood Suites, the first US hotel built using CLT, under construction in Huntsville, AL (Image Courtesy Lendlease)

Wood is Versatile

Different species of milled wood are ideal for certain projects but in general, wood’s light weight and workability make it easy to apply to virtually any application. Wood can typically be adapted in the field on-site, allowing for quick solutions if modifications are required. Wood is also an ideal material for additions, remodels and retrofits, and wood systems can be dismantled with relative ease and the materials repurposed or used again in another project.

Wood is Better for the Environment

A 2013 study by scientists from the Yale School of Forestry & Environmental Studies and the University of Washington’s College of the Environment evaluated various scenarios and environmental impacts associated with the use of wood as a construction material. While their findings may seem counterintuitive to those outside of the forest products sector, they demonstrate that buildings made from wood offer a number of ecological benefits over those built from concrete, brick, aluminum and steel. Builders use millions of tons of these materials every year and, while they have many valuable properties, they are energy-intensive to create, accounting for around 16 percent of the earth’s fossil fuel production. (If transportation and assembly are taken into account, the 16 percent is closer to 20-30 percent for these materials.)

The research, published in the Journal of Sustainable Forestry, estimated that the world’s forests contain roughly 385 billion cubic meters of wood. An additional 17 billion cubic meters is grown annually on top of that number, and only 3.4 billion cubic meters is harvested each year meaning that the earth’s forests are becoming more dense, which leads to catastrophic wildfires, pest infestations and disease.

A 2014 article by the researchers notes that, “Swapping steel, concrete, or brick for wood and specially engineered wood equivalents would drastically reduce global carbon dioxide emissions, fossil fuel consumption and would represent a renewable resource. What’s more, managed properly this can be done without loss of biodiversity or carbon storage capacity.”

“The 3.4 billion cubic meters of wood harvested each year accounts for only 20 percent of new annual growth. Increasing the wood harvest to 34 percent or more would have several profound and positive effects. Emissions amounting to 14-31 percent of global CO2 would be avoided by creating less steel and concrete, and by storing CO2 in the cell structure of wood products. A further 12-19 percent of annual global fossil fuel consumption would be saved, including savings from burning scrap wood and unsellable materials for energy.”

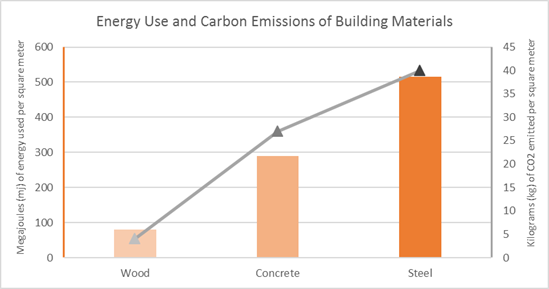

The researchers continue, “Building with wood consumes much less energy than using concrete or steel. For example, a wooden floor beam requires 80 megajoules (mj) of energy per square meter of floor space and emits 4kg CO2. By comparison, a square meter of floor space supported by a steel beam requires 516 mj and emits 40 kg of CO2, and a concrete slab floor requires 290 mj and emits 27kg of CO2. By using efficient harvesting and production techniques, more CO2 is saved through the avoided emissions, materials, and wood energy than is lost from the harvested forest…”

Wood Sequesters Carbon

Forests and the wood products derived from them have the unique ability to store carbon. In the case of a working forest managed according to industry best practices, the total amount of carbon sequestered in the forest is never lowered and there is no “carbon debt.” To put this process in perspective, consider the following:

- In order to produce 2.2 lbs. of timber, a single tree consumes 3.2 lbs. of CO2 and returns just over 2 lbs. of oxygen into the atmosphere.

- A single tree can absorb CO2 at a rate of roughly 48 lb. per year.

- When that tree is harvested and used to make wood products, byproducts and mill residues can be used for a number of purposes (including the creation of energy); nothing goes to waste.

- The carbon that single tree absorbed remains stored in the wood for the life of the product; 50 percent of the dry weight of wood is carbon.

It is far more preferable to store this carbon in vibrant forests and in the wood products derived from them than in the atmosphere where it could contribute to climate change. Despite the Maitland Planning & Zoning Commission’s contention that wood just “doesn’t work,” the overwhelming evidence—derived from human history, modern technology and environmental science—demonstrates otherwise.